- HOME

- Technical Information

- Technical Lineup

- Analysis Solutions for Semiconductor

Analysis Solutions for Semiconductor Manufacturing Process

Support your efficient development with Advanced Analytical Techniques

To continue to provide industry-leading service

- Over 40 years of accumulated know-how and many experts

- Ongoing investment in advanced equipment and facilities

- Development of analytical techniques themselves

Technology

Film Deposition

-

Chemical structure(FT-IR, ESR, STEM-EELS)

The physical and chemical structure at the interface of SiO2 thin films is known to be closely related to the electrical properties of semiconductor devices. We can provide various analytical techniques (AFM, EPR, FT-IR, TEM-EELS, etc.) for the evaluation at the interface between SiO2 and Si substrate.

P01140_Evaluation_of_the_interfacial_structure_of_a_SiO2_thin_film_on_a_Si_substrate.pdf

-

Composition(RBS, HFS)

Using ion scattering, as typified by RBS, depth profile can be acquired for thin films with various thickness, from ultrathin to thick films. High accurate composition including hydrogen can be obtained . Here depth profile of ultrathin SiN film, and RBS / HFS / NRA combination analysis of SiN film including carbon are presented below.

-

Density, Film thickness(XRR)

The new X-ray reflectivity instrument we introduced can evaluate a thickness and density of a ultra thin film and characterize a interface. Furthermore, we can know the whole pattern of the thin film on the wafer by a mapping mode measurement.

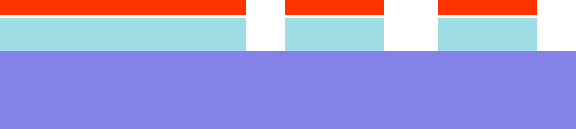

Photoresist Coating Exposure, Development

-

Photoresist chemical structure (GC/MS, micro-GPC)

It is very important for further miniaturization of semiconductor devices to investigate correlation between chemical structure of resist and Line Width Roughness (LWR). In this study, a novel sampling technique and Pyrolysis-GC/MS combined with micro-GPC enable usto analyze chemical structures of resist pattern in detail.

P01181_2014P015_Structural_analysis_of_photoresist_at_boundary_area_in_resist_pattern.pdf

-

Internal stress measurement

Internal stress of thin film can be determined by substrate bending, one of the method for stress measurement in our company. By using this method, temperature dependence of internal stress and stress distribution of thin film can also be clarified. We have two detecting types such as laser non-contact type and stylus one.

-

Cross-sectional observation (TEM)

It is important to clarify the structural change during annealing process in semiconductor device manufacturing. Heating behavior of materials can be observed at nm level by in-situ heating TEM. Information about structural change with heating can be utilized for process development.

P01978_In-situ_heating_TEM_observation_during_crystallization_of_amorphous_Si_film.pdf

Etching, Ashing, Cleaning

-

Residue (TOF-SIMS,IR)

Foreign substances in manufacturing process result in defective product and complains from customers. It is quite important to identify the cause of foreign substance to improve the process. Foreign substances are various in form and composition, from organics, inorganics and their mixture, and possesses different size ranging from several micrometer to millimeter. In order to obtain precise composition of the foreign substance, we have been developing sample preparation techniques , applying various instrumental apparatus and improving and expanding our original database. Case examples are shown below.

P00527_2007P093_Instrumental_analysis_for_the_elimination_of_foreign_substance.pdf

-

Damage, defect (CL)

We have developed advanced cathodoluminescence (CL) equipment with a completely new concept. The equipment is suitable for defect characterization of semiconductor devices since it has fully optimized electron gun and high-speed and sensitive spectral mapping system.

-

Metal impurities(ICP-MS)

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) enables high-sensitive, high-accuracy analysis of metal impurities on various semiconductor substrates. By applying the optimum preparation to each substrate and element, various metal impurities can be evaluated quantitatively.

P01449_2016P018_High-sensitive_analysis_of_metal_impurities_on_Si_SiC_substrates.pdf

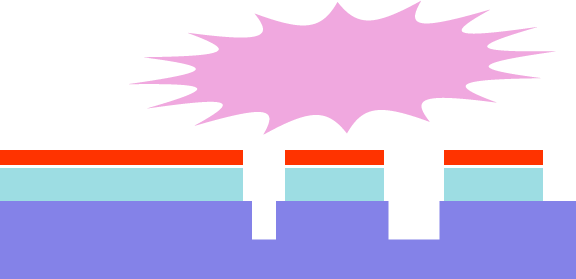

Dielectric film formation Surface planarization

-

Surface morphology (SPM)

In Toray Research Center, Inc., least noise-floor level in AFM measurements can be achieved by the high-performance active-type anti-vibration table and the converted measurement room with noise reduction. As a result, it is possible to estimate accurate quantitative values of roughness and discriminate the slight difference of them.

P01078_Least_noise-floor_AFM_in_the_world_Roughness_analysis_of_wafers_by_AFM.pdf

-

Damage, defect (Imaging PL)

We developed photoluminescence (PL) imaging system mainly for compound semiconductors by introducing highly sensitive CCD camera and optimizing illumination and detection system. Artifacts were drastically decreased and became highly sensitive to defects. It is especially suitable for low luminescent materials.

P01959_Defect_observation_by_highly-sensitive_photoluminescence_PL_imaging.pdf

Ion implantation , Anneal Gate dielectric film & Electrode formation

-

Dopant profile (SIMS)

With the development of high voltage termination technology of SiC devices, detection of nitrogen at ultra low concentration has become important. Recently, the detection limit of N in SiC materials at our company have been greatly decreased from 1015cm-3 to 1014cm-3 through improvement of instrumentation, measurement conditions, and data-analysis methods. Since variation of signal intensity is decreased, it is also possible to evaluate minute changes in the nitrogen concentration.

P01589_Detection_of_nitrogen_at_ultra_low_centration_in_SiC_by_SIMS.pdf

-

Composition & Grain distribution (EBSD, SEM-EDX)

This slide introduces an example of using SEM-related equipments, EDX detectors and transmission EBSD to analyze the cross-section structure of SiC MOSFET (commercially available power devices). In these SEM-based analysis, the spatial resolution of high-precision EDX and Transmission EBSD can reach about 100nm and 20nm respectively.

P01585_Elemental_and_Crystal_Orientation_Analysis_of_SiC_MOSFET.pdf

-

Carrier distribution (SCM,DPC-STEM)

By scanning capacitance microscopy (SCM) and differential phase contrast imaging (DPC) in scanning transmission electron microscopy (STEM), Analysis examples of carrier distribution and p-n junction of SiC MOSFET device are shown.

P01811_Analysis_of_carrier_distribution_and_p-n_junction_of_Power_semiconductor.pdf

-

Ion implantation damage (CL)

Point defect evaluation of ion implanted and annealed Silicon substrate by Cathodoluminescence. Optimization of ion implantation conditions and anneal conditions are very important. Cathodoluminescence is the powerful tool that is very convincing for those solutions to the problem.

S00263_Characterization_of_defects_generated_by_ion-implantation_by_cathodoluminescence.pdf

-

Stress (Raman)

Stress evaluation of TSV (through-silicon via) by Raman microscopy. Raman microscopy is the powerful tool for measuring stress of semiconductors. Feature of stress analysis in TRC is high precision measurement (within ± several MPa).

-

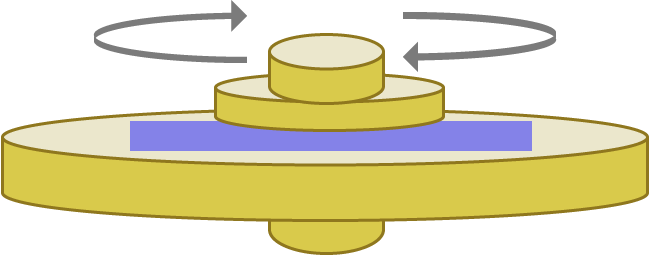

Ion implantation service

Implanter: ・ ULVAC IMX-3500RS (Medium current implanter, electorostatic scan system) Capabilities: ・Rapid turnaround(within-12hour-shipping is possible if required) ・Energy : (3keV)~10keV to 200keV (up to 400keV using doubly charged ions) ・Dose : 5.0×1010 ~1.0×1017 ions/cm2 ・Irregularly shaped substrate, 2 to 6inch wafers are available